New battery security rules regarding thermal runaway have prompted an evolution in pack design

In 2020, the Chinese language authorities issued GB 38031, a brand new nationwide security normal for electrical autos. It set a brand new requirement for car security wherein passengers should obtain at the least a five-minute warning to exit the car if a battery thermal runaway occasion is detected. Earlier this 12 months, a revised normal was issued, which tightened these security necessities significantly. Whereas the five-minute egress rule nonetheless stands, the usual is now extra prescriptive round failure modes, testing, documentation and efficiency.

Thermal limitations are one of many key applied sciences required to satisfy this normal. In pouch- or prismatic designs, thermal limitations are usually positioned between every cell to function a firewall. If one cell goes into thermal runaway, thermal limitations lower off the cell-to-cell conduction that’s the first pathway for thermal power to journey. Thermal limitations can’t cease the spark, however that may delay or forestall it from lighting the fuse. Whereas GB 38031-2025 doesn’t explicitly require thermal limitations, it’s now a lot more durable to adjust to the usual with out them.

On the similar time, EV batteries are getting larger. Greater power densities, tighter packaging, and shorter design cycles imply there’s much less room — actually and figuratively — for error. To forestall a single-cell thermal runaway from propagating into adjoining cells, designers have to pack as a lot thermal resistance as potential into the tiny gaps between cells. However how a lot is critical?

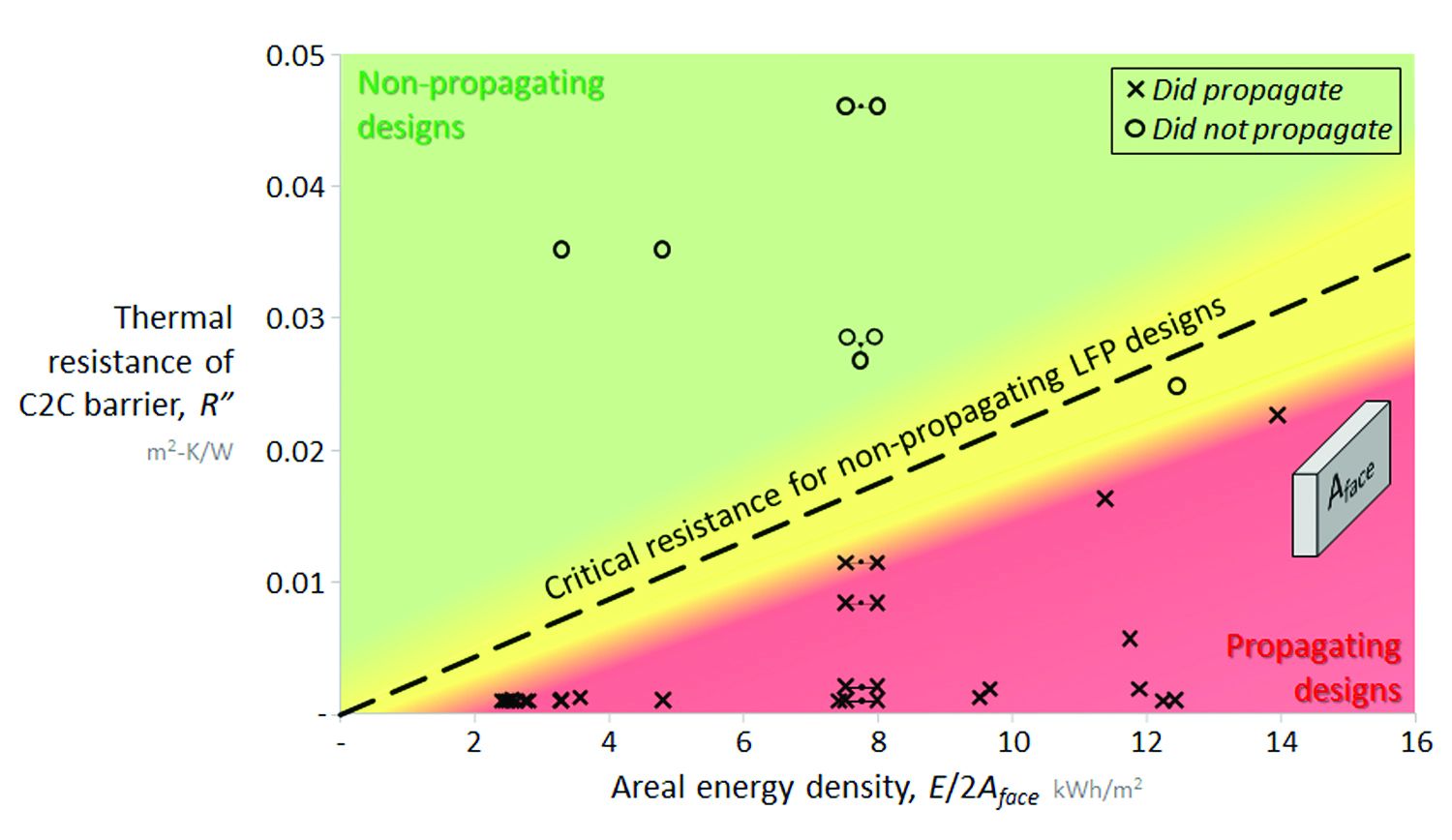

It seems there’s a easy proportionality between the power content material of the cells, the cell-face space, and the important thermal resistance of the thermal barrier. That proportionality will be discovered by conducting a number of thermal runaway checks wherein thermal limitations of various thickness are trapped between two cells in an open-air atmosphere. By triggering one cell into thermal runaway and monitoring whether or not the opposite cell follows it, two populations will be recognized: propagating and non-propagating designs. These populations are separated by a boundary denoting the important thermal resistance under which thermal propagation will happen.

It seems there’s a easy proportionality between the power content material of the cells, the cell-face space, and the important thermal resistance of the thermal barrier. That proportionality will be discovered by conducting a number of thermal runaway checks wherein thermal limitations of various thickness are trapped between two cells in an open-air atmosphere. By triggering one cell into thermal runaway and monitoring whether or not the opposite cell follows it, two populations will be recognized: propagating and non-propagating designs. These populations are separated by a boundary denoting the important thermal resistance under which thermal propagation will happen.

This evaluation exhibits that thicker, extra energetic cells require additional thermal resistance to stop propagation by cell-to-cell warmth switch. When the identical sort of testing is performed on NMC cells, the same linear boundary exists however with a taller slope. Resulting from their decrease trigger- and better peak-temperatures throughout runaway, NMC designs can require 50-60% extra insulation for a pack of the identical power capability.

Aspen Aerogels’ engineers have an in-depth understanding of the complicated mechanisms of thermal runaway. They design PyroThin cell-to-cell limitations with a system-level method to not solely deal with thermal propagation but additionally maintain cell well being and efficiency all through the pack’s lifecycle.